Coolant Filling Machine

Home » Fluid Handling System » Evac And Filling Machine » Coolant Filling Machine

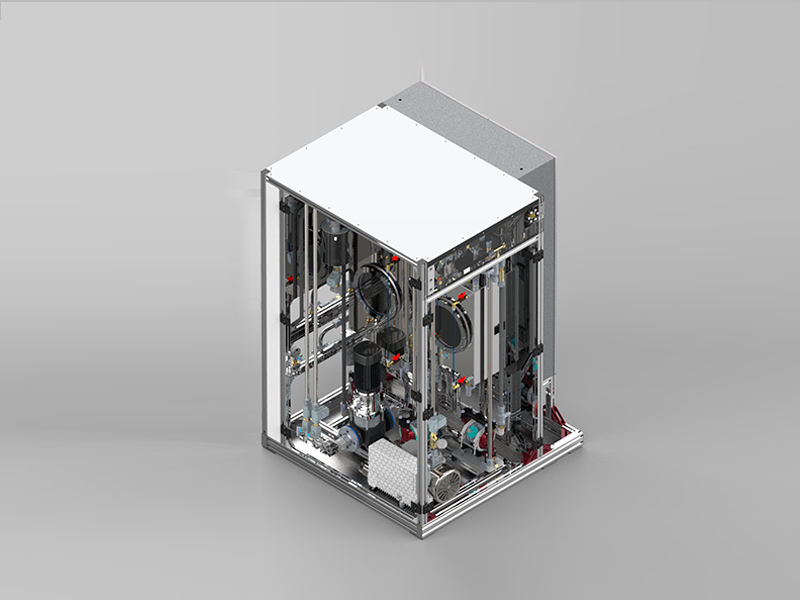

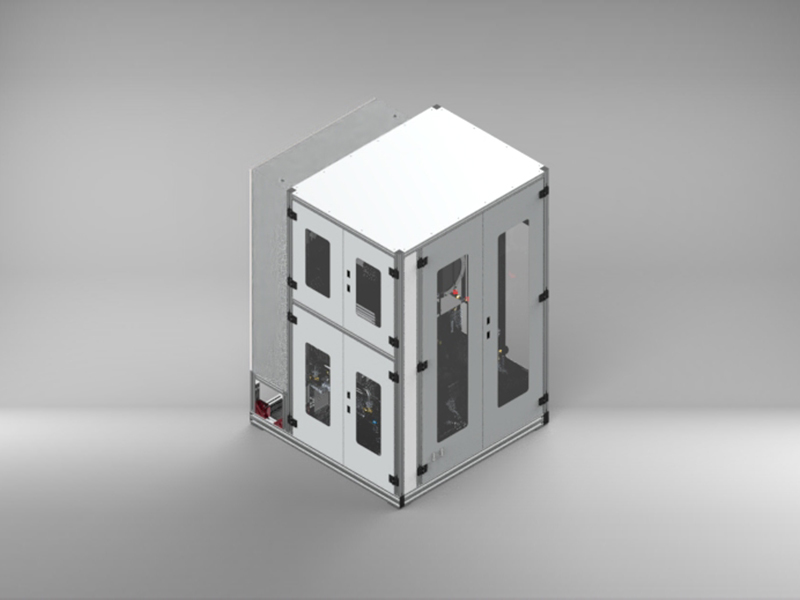

Patvin Engineering’s Coolant Filling Machine is a comprehensive solution for precise, efficient, and reliable coolant filling across diverse industries. Applicable for all vehicles – trucks, trailers, cars, agriculture, buses, and earthmoving equipment, this advanced machine empowers your production processes with enhanced precision, efficiency, and reliability. By ensuring the accurate and consistent filling of coolants, this machine contributes significantly to the quality of your end products while optimizing your overall production operations.

Coolant Filling Machine Technical Specifications:

- Suitable for a wide range of tact times, from 4-27 JPH.

- Delivers a strong vacuum of 25mbar at the gun tip for effective air removal.

- Fills coolant at a rate of 10 to 14 liters per minute (LPM).

- Ensures exceptional filling accuracy of 2mm on the coolant reservoir or degassing bottle.

- Maintains a precise Glycol to Water ratio mixture within +/- 2%.

- Available in both single and multi-ratio configurations to meet your specific needs.

- Employs a pneumatic clamping gun that eliminates dripping for a clean and efficient operation.

- The gun itself is lightweight, weighing between 2.2 and 3.0 kilograms.

- Boasts an impressive 99% uptime, minimizing downtime and maximizing productivity.

- Includes a built-in leak testing facility with positive air pressure for thorough quality control.

- Generates reports on the filling process for documentation and analysis purpose

Coolant Filling Machine Features

- Provides a fully automatic process sequence with an audio-visual alarm system to keep operators informed.

- Offers the option for manual operation for greater flexibility.

- Features a customizable machine layout to perfectly integrate with your workspace constraints.

- Allows for customization of the gun design to suit your specific application requirements.

- Eliminates the need for manual top-up of coolant after the drive test, ensuring proper filling from the start.

- Considers factors such as customer floor space, vehicle parameters, and cycle time during the design process.

- Enables model or variant selection through a barcode scanner or MES/AMES/VTS system, automatically selecting the appropriate filling parameters.

- Integrates condition-based and time-based alarms to proactively identify potential issues.

- Provides fault diagnosis through the HMI for efficient troubleshooting.

- Monitors energy consumption to optimize machine operation.

- Offers real-time process monitoring on the HMI for enhanced control.

- Incorporates a quick replacement system for the gun, minimizing downtime in case of maintenance needs.

- Utilizes high-quality components from reputable manufacturers, ensuring long-lasting performance and reliability.

Application

- Battery / Traction Cooling System

- Radiator Coolant Filling Machine

Conclusion

Patvin Engineering’s Coolant Filling Machine is a comprehensive solution for precise, efficient, and reliable coolant filling across diverse industries. Applicable for all vehicles – trucks, trailers, cars, agriculture, buses, and earthmoving equipment, this advanced machine empowers your production processes with enhanced precision, efficiency, and reliability. By ensuring the accurate and consistent filling of coolants, this machine contributes significantly to the quality of your end products while optimizing your overall production operations.

FAQs

Our coolant machine handles all vehicle types including trucks, trailers, cars, buses, and earthmoving equipment. The system adapts to different vehicle specifications through customizable gun designs and flexible layouts

The machine fills coolant at 10-14 liters per minute with exceptional accuracy of 2mm. It maintains precise glycol-to-water ratios within +/-2% while achieving 4-27 vehicles per hour depending on requirements.

The system features automatic process sequencing with audio-visual alarms and barcode scanner integration. It selects filling parameters automatically through MES/AMES/VTS systems and eliminates manual coolant top-ups after drive tests.

Yes, our automatic coolant filling machine includes built-in leak testing with positive air pressure. The system generates detailed filling reports and provides real-time process monitoring through HMI interface.

The machine offers 99% uptime with quick gun replacement systems for minimal downtime. It features condition-based alarms, fault diagnosis through HMI, and uses high-quality components from reputable manufacturers for long-lasting performance.