In a high pressure world of manufacturing, precision is everything.

Nobody wants a slow, messy, and inconsistent system. A single mistake can mean the difference between a flawless product and a costly rework or rejection.

Our client, a leading automotive manufacturer, was struggling with their windshield bonding process since the Truck Cabin glass was big and heavy.

Their old process, using a single component sealant, was time-consuming and offered limited strength as well and longer time was required for the sealant material to cure and gain full adherence strength.

They knew they needed a change, so they opted for a Fast curing robust two-component material. However this new solution came with a challenge: it was higher viscosity and much more complex than the previous sealant due to the addition of a booster material which would help faster curing and better adhesion strength.

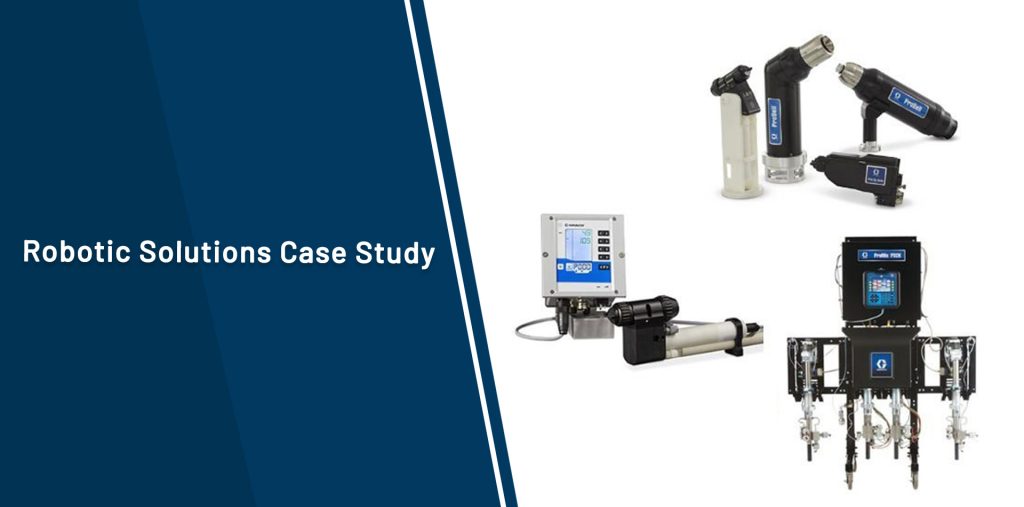

That’s when we introduced them to our first-of-a-kind robotic application system designed specifically for their needs by Patvin Engineering Private Limited. It included :

A KUKA Robot: Our tireless worker, programmed for precise application, ensuring consistent and reliable windshield bonding.

Advanced Material Handling: A temperature conditioning system and specialized pumping system which ensured that the new, higher viscosity sealant flowed smoothly.

Custom Dosing System: The two separate dosing units, one for the Component A and another for Component B ( booster ) controlled with pinpoint accuracy, and delivered the perfect amount to maintain the mix ratio with high accuracy and repeatability.

High Precision Dispense valve with Rotation – A very precise dispensing valve which can dispense and change flow rate on the fly with reference to the robot tip speed and a Teflon nozzle designed to provide the right size of the glue bead.

The results?

It was a game-changer for our client!

Apart from being a more sustainable operation because of the use of entirely new materials and solutions, it also led to:

Faster Production

Reduced Material Wastage

Improved Quality and

Lower Production Cost

For them, it was a win-win situation.

This is just one example of how Patvin’s innovative robotic solutions transformed the manufacturing processes. We can tailor a system for your specific needs as well, whether you’re in automotive, aerospace, or anything in between!

FAQ’s

- What does it mean that robotic solutions enhance the efficiency of windshield bonding in production?

Robots apply sealants exactly where needed, giving stronger bonds and quicker results. They remove variability from hand application by allowing control of the flow rate, temperature, and motion. - How does automation improve safety when working with adhesives?

They reduce the need for people to handle dangerous glue directly. Robots handle high heat and pressure safely, so workers stay out of danger. - What are the advantages of using rotating valves in robotic fluid dispensing systems?

These valves give operators better control, so there’s less dripping or excess adhesive. It ensures every bond is neat, even, and done without extra mess or waste. - Can robotic dispensing systems handle high-viscosity materials in automobile manufacturing?

Yes, robots are strong enough to deal with thick glues and sealants. They make sure the glue flows evenly by managing heat and pressure.