Project Location: India

Industry: Automotive

Customer: Four Wheeler Company

Customer Requirement:

The customer faced a challenge of increasing rejections in the Paint shop due to faulty color selection by operator. Also manual color change was time consuming, affecting the paint shop efficiency. They were looking for a system that could automate the color change action avoiding operator dependency, thus reducing rejections and making the

process quick and efficient.

System Specifications:

We delivered a systems that allows automatic recovery of the non-applied paint & cleaning of the system – Patvin’s RECOCLEAN system, a pig-less paint-push-back-system between Color Change Units and Atomizer.

RECOCLEAN uses dry air to push back paint from the Atomizer to the Color Changer and clean the fluid line including built-in components.

A unique feature of the system resides in the ability of the discharge system to automatically separate and isolate the original paint from the new color paint, so that the purged paint may be collected in a segregated container and re-used, enabling significant cost savings.

System Key Components:

• PLC control panel (Qty- 1no) – Receives color input from Automation control and Initiates color change

• Color change Valves (Qty- 1 set /stn.)

• Solenoid valve Bank (Qty – 1 no/stn.) – Receives command from PLC and triggers CCV

• Gun Flush Box (Qty-2 nos /stn.) – Triggers spray gun during color change operation

• Color sensor (Qty- 2 nos./stn.) – Ensures push of paint during color change

• Pulse valve (Qty- 2 nos./stn.)

System advantages

• Paint recovery up to Gun.

• Reduction of Guns & Hoses in Manual Spray Zone offering a cleaner interior.

• Consistent Smooth & Seamless Color Change in shortest possible time (< 5 secs), increasing paint shop efficiency.

• Elimination of faulty color selection by the operator, specially in close Shades.

• Reduces the paint and cleaner consumption. Paint Recovery >/=70%, enabling cost savings.

• Easy to introduce into existing paint systems.

• Faster payback time.

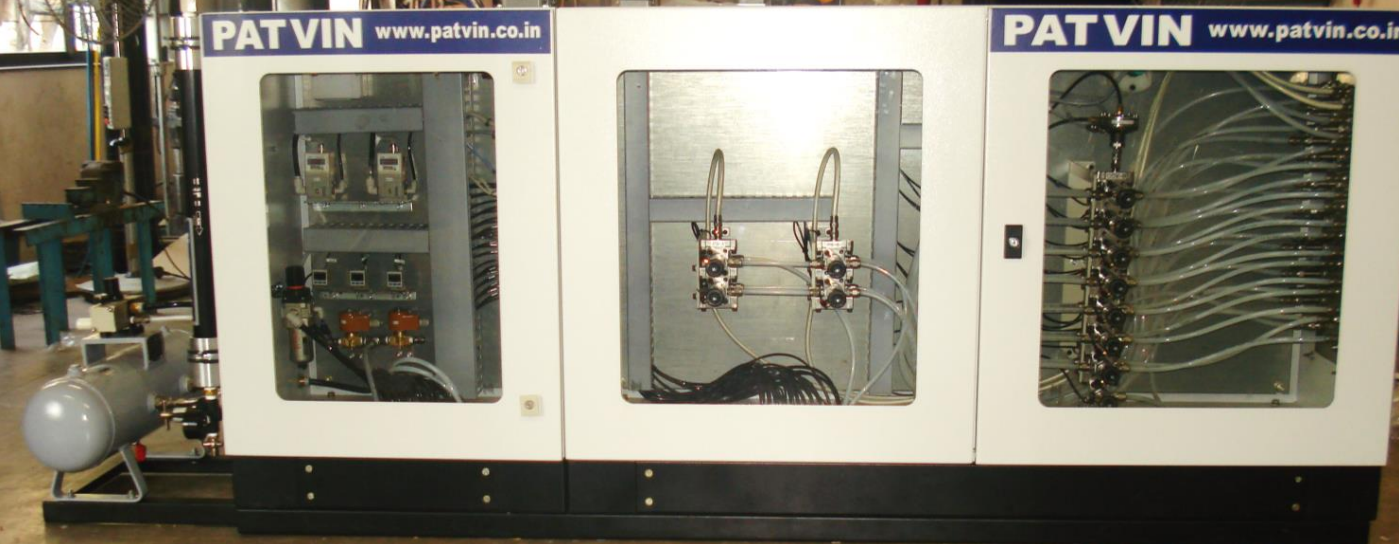

PATVIN’S RECOCLEAN UNIT:

FAQ’s

- What is a paint automation system?

A paint automation system is an industrial automation solution designed to mechanise the coating or painting process on various products. It improves painting precision and ensures uniform quality. The system reduces effort and paint use, helping the painting process run faster and smoother. - What was the primary issue of this case study?

The main issue faced by the customer in this case study was frequent production stoppages caused by manual, time-consuming color changes in their old paint system. This manual process slowed down work and wasted a lot of paint during color cleaning. - What was the solution that Patvin applied to the manual color change issue?

Patvin developed an Auto Colour Change System to solve the manual colour change issue in automotive painting processes. It uses smart valves and controls to switch colors quickly and keep the line moving. - How does paint automation reduce the wastage of paint?

Paint automation reduces paint wastage by optimizing the flushing process during color changes. It carefully manages flow rates so that almost no paint is left in the lines. It prevents human errors and saves paint that would usually be lost in manual setups.