- CAPABILITIES

- SERVICES

- COMPANY

- INDUSTRIES

- BLOGS

- CASE STUDIES

- CAREERS

- CONTACT US

Drum Tumbler

Home » Capabilities Overview » Paint Application System » Accessories » Drum Tumbler

Patvin Engineering is the leading supplier of single and double drum tumblers and has over three decades of expertise.

Drum tumblers or drum mixer tumblers are used to mix various substances inside a closed drum without any mess or contamination.

Features of Drum Tumblers:

- Blend batches of powder

- Ensure uniform batches

- Mix drums of paint, oils, urethane resin, plastisol, glue, dyes, flavors, etc.

- Mix chemical drums into homogeneous product prior to use

- Grind and smooth parts in media

- Mix products inside sealed 1 to 5 gallon (4 to 20 liter) cans or pails.

- Reduces hazards and saves clean-up.

“Low Shear” Cavity Free Connection Fittings

All Hosco connection fittings feature its new “Low Shear” design that incorporates a taper-to-taper connection, which eliminates the blunt end or shelf surface found in conventional fittings. The design enhances Hosco’s smooth bore, cavity free product line helping metallic paint finishes retain their color, luster and quality while reducing system pressure loss, speeding installation procedures and furthering overall safety.

Quick Disconnect “No-Spit” Fittings

Hosco paint quick disconnects work precisely with Hosco stems to eliminate the accumulation of paint and sludge that forms during everyday use of paint quick disconnects sets. The fittings eliminate the need for frequent solvent flushing or washing, cleaning away accumulated waste to prevent paint pits.

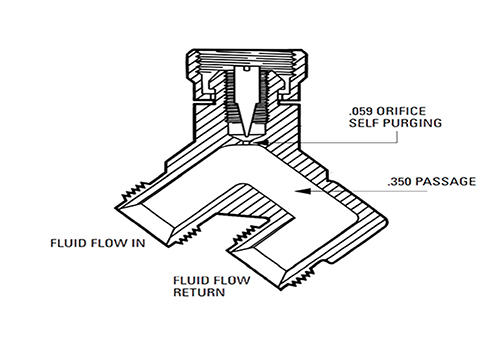

Restrictor/Regulator

The Hosco HHR-6 restrictor/regulator incorporates a restrictor on a regulated paint outlet and then permits adjusting it to the desired flow rate to the spray gun. This helps attain maximum accuracy and repeatability while maintaining spray gun control even in the extremely low range. This restrictor/ regulator is well suited for painting large structures with their inherent elevation changes from top to bottom such as aircraft, trucks and buses or for electrostatic air spray/HVLP painting applications.

Agitator for Pails

Designed for a wide variety of industrial and automotive applications. Agitators ensure paints and fluids are agitated precisely to keep paint solids in suspension and maintain optimum finishing characteristics.

Designed for a wide variety of industrial and automotive applications. The agitators ensure paints and fluids are agitated precisely to keep paint solids in suspension and maintain optimum finishing characteristics. Binks agitators are suitable for a wide range of viscosities and paint material types including solvent based, waterborne and many other fluids.

Agitators for Drums

Binks Agitators can be purchased independently or mounted to container covers. The speed of the propeller shaft is determined by fluid.

Designed for a wide variety of industrial and automotive applications. The agitators ensure paints and fluids are agitated precisely to keep paint solids in suspension and maintain optimum finishing characteristics. Binks agitators are suitable for a wide

range of viscosities and paint material types including solvent based, waterborne and many other fluids.Note: Binks recommend the use of an air oil lubricator with these air driven agitators.

Model 41-3304 for 205 litre (55 Gallon) Drums

Stainless Steel agitator and drive assembly only

Speed: Speed of propeller shaft is determined by fluid, 1000 RPM maximum

Air Supply: Air supply to the motor should be 4 bar (60 psi) gauge pressure minimum.

Hose & Tubing Connectors

Hosco line of quality products.

Complete line of hose fittings for most every type of application.

Complete line of hose fittings for most every type of application.

Hosco PA Hose Connectors are designed to provide safe and non-conductive connections of hose and tubing using the robust and industry leading Hosco barb and nut style retention system. These connectors significantly exceed the performance of other style connectors and provide the highest level of safe and reliable connections found today for use in flammable or hazardous fluid handling.

Generally, these PA (PolyAmide) connectors are used in ungrounded or high dielectric designed systems to minimize the concerns for static discharge (arcs or sparks) or pinholing/dielectric burn thru of thermoplastic components in the fluid delivery system. The PA family of hose connectors are available in common sizes of fractional inch or metric hose connection ends, and in straight or compact 90 degree configurations. The connection point is available in two common ends- NPT/BSPT(PT) or NPS/BSPP(PF) with single or double dielectric gasket/seal design.

The end connections are 1/8”, 1/4”, and 3/8” sizes.

PolyAmide Materials of Construction suitable for most paints, coatings or solvents with a wide range of chemical compatibility.

One common style of connector for fractional inch and metric hoses or tubes with straight or 90 degree styles.

Robust designs

Mechanical retention of hose and tube to insure safety and trouble free operationHosco PA Hose Connectors are designed to provide safe and non-conductive connections of hose and tubing using the robust and industry leading Hosco barb and nut style retention system. These connectors significantly exceed the performance of other style connectors and provide the highest level of safe and reliable connections found today for use in flammable or hazardous fluid handling.

Generally, these PA (PolyAmide) connectors are used in ungrounded or high dielectric designed systems to minimize the concerns for static discharge (arcs or sparks) or pinholing/dielectric burn thru of thermoplastic components in the fluid delivery system. The PA family of hose connectors are available in common sizes of fractional inch or metric hose connection ends, and in straight or compact 90 degree configurations. The connection point is available in two common ends- NPT/BSPT(PT) or NPS/BSPP(PF) with single or double dielectric gasket/seal design.

The end connections are 1/8”, 1/4”, and 3/8” sizes.

PolyAmide Materials of Construction suitable for most paints, coatings or solvents with a wide range of chemical compatibility.

One common style of connector for fractional inch and metric hoses or tubes with straight or 90 degree styles.

Robust designs

Mechanical retention of hose and tube to insure safety and trouble free operation

Prefis Connectors

Easy to use Hosco Prefis Connectors

Installing new or modifying existing piping systems is easier with the Hosco PreFiS connector family of products.

Installing new or modifying existing piping systems for fluids such as paint or high viscosity sealer header systems has never been faster or easier than with the Hosco PreFiS connector family of products.

Solvent Distillation System

In industrial applications, distillation is a process widely used to purify a mixture or separate contaminants from a mixture. The specific goal of the distillation process varies from one application to another.

In chemical or food manufacturing, it usually aims to purify a product by removing all toxic or impure materials. The end result is a mixture that is highly concentrated or purified from all contaminants.

However, this could also be used to recover a contaminated mixture, such as waste cleaning solvent. In this case, the concentrated mixture is rejected and retaining the distilled solvent becomes the objective of the process.

Our solvent distillation systems are especially designed to reclaim waste solvents generated from a variety of industrial applications, including:

Recycling Waste Cleaning Solvents

Flexo/Litho Printing Solvent Recovery

3D Printing Solvent Recovery

FAQs

Drum tumbler is designed to mix contents efficiently, using a rotating mechanism, ensuring through mixing of materials such as powders, liquids and granules.

Tumbler machines work by operating through a rotating drum in a specific motion allowing the contents to move from end to end of the drum providing a uniform mix. This is ideal for heavy materials that require thorough agitation.

A drum tumbler mixer vigorously mixes by rotating drum end to end, whereas a drum roller simply rolls the drum alongside, not always achieving the same mixing efficiency for all materials.

A drum paint mixer can be used for multiple materials other than paint, thus being able to mix adhesives, chemicals, and other vicious substances effectively, ensuring consistent product quality across different applications.

Benefits of using a mixer tumbler:

Product Consistency

Versatility

Efficient Operation

Ease of Cleaning

Optimal Efficiency

Reduced Downtime

There are multiple types of drum tumblers available including end-over-end and tilt-to-load models each being designed for specific needs. Patvin Engineering has been providing multiple types of drum tumblers for years according to your needs.

By regularly inspecting your drum tumbler you can avoid its wear and tear. Clean your machinery after every use to prevent contamination ensuring all parts are lubricated and functioning properly to extend its lifespan.