- CAPABILITIES

- SERVICES

- COMPANY

- INDUSTRIES

- BLOGS

- CASE STUDIES

- CAREERS

- CONTACT US

EV Battery

Home » Capabilities Overview » EV Battery

Leading producers of production technologies for businesses in the battery and electromobility sectors include Patvin. We provide Graco-powered equipment for effective and superior battery and electric vehicle (EV) manufacturing along the value chain.

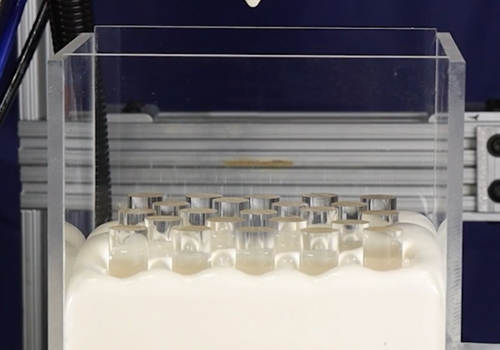

One of the main components of electric vehicle battery technology is lithium-ion batteries. With cutting-edge Graco dispensing technologies for solvent recovery as well as coating and drying electrodes, Patvin is well-represented in this significant, future-focused market. Graco fully automated lithium-ion battery assembly technologies round out the offering. Our product offering also includes applications of thermal interface materials and testing technology for high-voltage circuits of electric vehicles at the end of the assembly line, in addition to structural bonding solutions for battery cell and module assembly. We also provide cylindrical cells adhesive solutions that ensure strong bonding and thermal stability during battery pack assembly.

FAQs

Battery sealing is used for protecting the internal components for EV, preventing any moisture and dirt from entering which may cause any damage. Proper sealing enhances the battery's performance and lifespan.

Adhesives and sealants hold EV battery parts firmly in place and keep them safe. These materials keep the battery safe by stopping electrical leaks, managing temperature, and adding support.

Structural bonding, including applications like EV battery box bonding, offers several benefits to EV battery assembly:

- Weight Reduction

- Design Flexibility

- Improved Thermal Management

- Increased Structural Integrity

- Enhanced Safety

- Simplified Manufacturing Processes

A gap filler for batteries is used to fill spaces between the components inside a battery pack, helping reduce any noise, vibration and thermal expansion. You can use it when assembling battery packs to improve performance and protect sensitive parts.

A pouch battery pack bonding adhesive is used with flexible pouch batteries to provide strong adhesion which allows flexibility in battery design, ensuring that the pouch remains intact during operation, enhancing safety and reliability.

Our Happy Clients